Effective production management is based closely on how nicely substances are planned, particularly lumber. Lumber bureaucracy tis he backbone of structural frameworks, making accurate planning vital for keeping clean operations. Without proper planning, tasks can face shortages, fabric waste, and disorganized work sites, all of which compromise efficiency and value-effectiveness.

Modern construction projects frequently contain tight schedules, a couple of groups, and confined on-page garage. In these surroundings, poorly predicted or uncoordinated lumber can disrupt workflows, put off development, and create additional fees. By adopting practical lumber making plans strategies, developers can streamlinefabricationt, enhance on-site organisation, and decorate ordinary productiveness.

Organizing lumber making plans isn’t always pretty much counting portions—it’s approximately aligning cloth requirements withproductionn sequencing, delivery schedules, and actual global web page situations. This guarantees that materials are usually to be had whilst wished, decreasing downtime and helping easy progress.

Starting With Accurate Measurement and Analysis

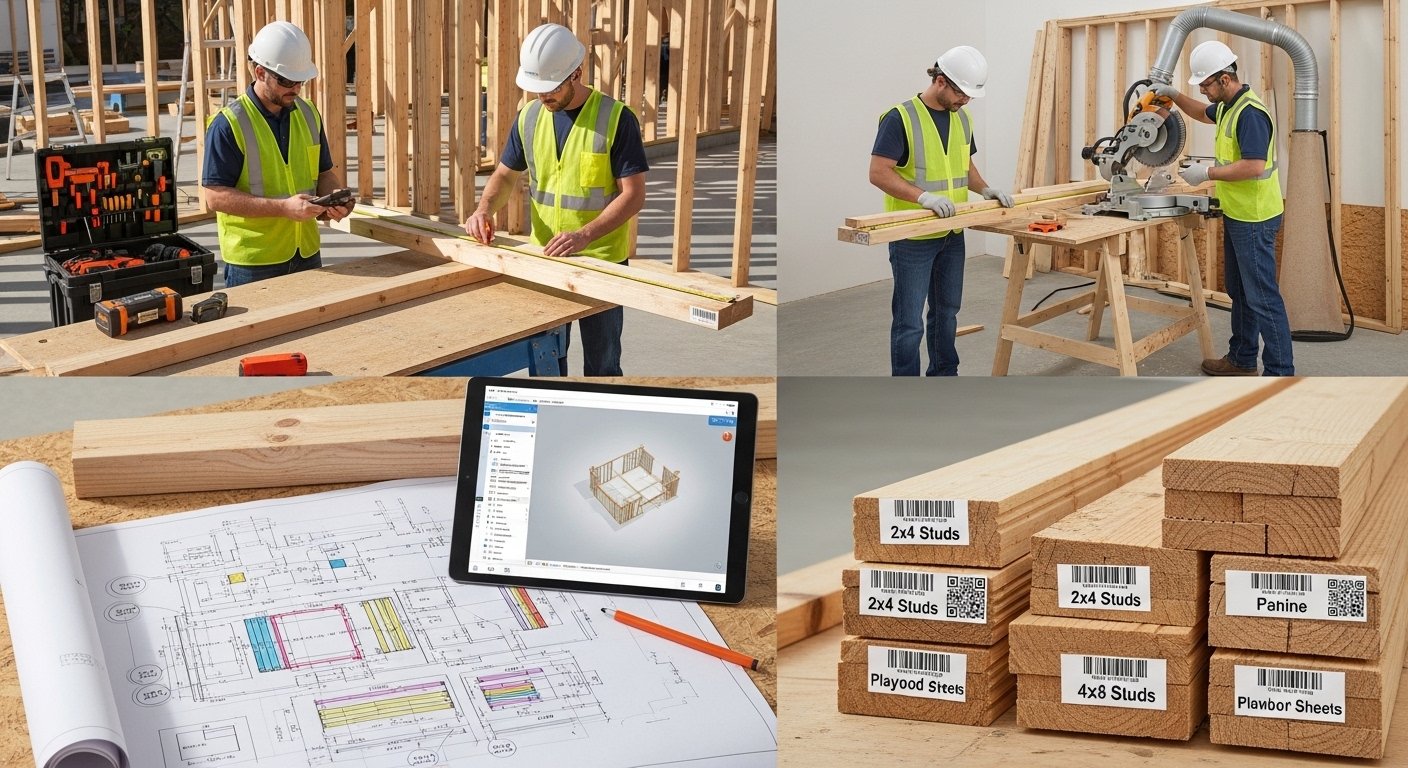

The first step towards organized lumber planning is a careful review of creation drawings, consisting of floor layouts, wall sections, and roof framing plans. Accurate interpretation of these plans permits estimators to recognize the suitable dimensions, issue placements, and amount necessities for each piece of lumber.

At this level, lumber takeoff turns into a critical approach. By systematically extracting measurements from scaled drawings, professionals create a comprehensive stock of all required lumber additives. This approach reduces reliance on difficult estimates and gives a stable foundation for ordering substances efficiently.

For instance, don’t forget planning wall studs for a construction with a 240-foot wall and 16-inch spacing:

240 ÷ 1.33 (spacing in feet) ≈ , a hundred and eighty studs

Adding 10% waste: one hundred eighty × 1.10 ≈ 198 studs required

This calculation ensures that the expected lumber matches actual necessities, reducing the threat of on-site shortages or pointless surplus.

Organizing Materials for Phase-Based Workflow

Once quantities are determined, lumber should be prepared to align with creation levels. Material for basis work, wall framing, roofing, and finishing should be scheduled and brought consistently with the series of duties. This prevents clutter, protects lumber from harm, and guarantees that employees have on the spot get right of entry to to the pieces they want.

Phased employer of lumber additionally permits crews to work successfully without searching through big piles of cloth. This strategy reduces dealing with time, prevents accidental harm, and keeps the website purifier and safer.

Many contractors collaborate with a professional Construction estimating Company to increase specific transport schedules. These specialists use enjoy and information of production sequencing to plan how materials are staged, making sure that lumber supply fits venture timelines and on-website online workflow.

Incorporating Waste Factors and Real-World Adjustments

Even the most accurate takeoff calculations need changes for real-global conditions. Cutting losses, broken materials, layout adjustments, and installation nuances all have an impact on how much lumber is actually required. Practical planning constantly consists of waste allowances to ensure continuity in creation.

For instance, planning ground joists spaced 16 inches apart across a 48-foot span:

48 ÷ 1.33 ≈ 36 joists

Each joist is 14 feet long: 36 × 14 = 504 linear ft

Adding eight% waste: 504 × 1.08 ≈ 544 linear feet

Waste factors vary depending on assignment complexity. Roofs with a couple of angles or walls with numerous openings may additionally require higher allowances. Accounting for those factors earlier prevents shortages and decreases emergency orders, maintaining the website online, prepared, and operations flowing easily.

Leveraging Data and Experience for Improved Efficiency

Modern construction groupsincreasinglyf depend upon historical facts and enjoy refining lumber-making plans. By comparing envisioned cloth desires with actual usage from preceding tasks, estimators benefit ifrom nsights into common waste prices, overages, and setup challenges.

Construction estimating services offer valuable aassistancein this region. By keeping data from more than one task, these services pick out trends in cloth intake and help forecast destiny requirements more accurately. This permits builders to order the proper amount of lumber, reduce overstock, and enhance on-site fabrication control.

Example Calculation

Wall framing: 220 linear feet, 16-inch stud spacing

220 ÷ 1.33 ≈ one hundred sixty-five studs

Including 10% waste: 165 × 1.10 ≈ 182 studs

Floor joists: forty-two-foot span, sixteen-inch spacing

forty-two ÷ 1.33 ≈ 32 joists

Each joist is 14 feet long: 32 × 14 = 448 linear feet

Adding 8% waste: 448 × 1.08 ≈ 484 linear toes

These calculations show how careful planning, mixed with practical adjustments and ancient information, improves cloth wear and prevents website delays.

Read more: Dimensional 2×6 Lumber Sizes Applied in Building and Remodeling of Home

Final Thoughts

Professional lumber planning methods are crucial for preserving prepared and productive production wwebsites By combining accurate size strategies, phase-based fabrication, realistic waste adjustments, and data-driven insights, builders can streamline workflow, reduce litter, and save on high-priced delays.

Using dependent methods like lumber takeoff, consulting with a Construction estimating Company, and leveraging Construction estimating offerings ensures materials are introduced and used eefficiently This approach permits construction groups to maintain excessive productivity, acquire value control, and supply initiatives on time.

Ultimately, disciplined lumber planning supports both operational performance and long-term undertaking success.

Frequently Asked Questions

- Why is prepared lumber making plans essential for production websites?

It guarantees materials are available when wanted, prevents litter, and supports continuous workflow.

- How do phased deliveries enhance website productivity?

Delivering materials in line with creation phases reduces garage troubles and makes it less difficult for crews to get eaccessto the right lumber at the right time.

- What factors must be considered when estimating lumber necessities?

Design complexity, slicing waste, broken substances, and structural openings all impact correct lumber estimation.

- Can beyond undertaking facts improve lumber planning accuracy?

Yes, studying historical utilization allows refining calculations and predicting fabric wishes more accurately.

- Are those planning techniques useful for smaller tasks?

Absolutely. Structured estimation, waste management, and phased deliveries enhance performance and decrease costs for initiatives of all sizes.